News

Pineville Schools break ground for athletic field improvements

The Pineville Independent School Board held a ground-breaking ceremony on Friday as work has started on $3.29 million ...

The Pineville Independent School Board held a ground-breaking ceremony on Friday as work has started on $3.29 million ...

A large crowd packed the Crater City Hub Monday night for UNITE Bell County’s inaugural Community Heroes event. ...

The featured entertainment for the Kentucky Mountain Laurel Festival’s opening ceremony has been announced. Struggle Jennings with Caitlynne ...

An employee at a Middlesboro funeral home was one of three people killed in a crash on Saturday ...

Average gasoline prices in Kentucky have risen 18.4 cents per gallon in the last week, averaging $3.39/g today, ...

By Billy Holland Columnist We all know the feeling of having something on our minds that we have ...

During Tuesday’s Bell County Fiscal Court meeting, County Attorney Chris Douglas invited everyone out to the 16th annual ...

Mayor Scott Madon announced that all the necessary funding has been secured to complete the City of Pineville’s ...

The 2024 DanceBlue marathon, which began at 8 p.m. Saturday, saw more than 800 University of Kentucky students ...

By Samantha Mills Bluegrass Newsmedia According to the American Heartworm Society, more than one million pets in ...

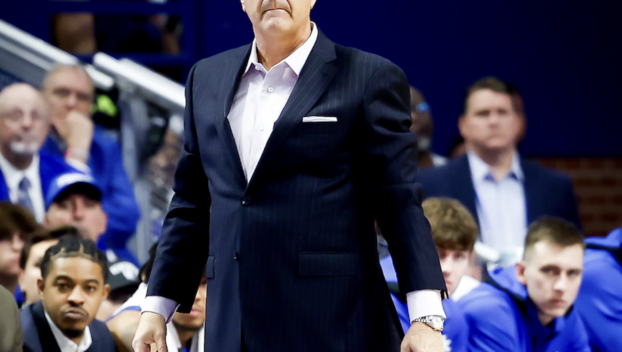

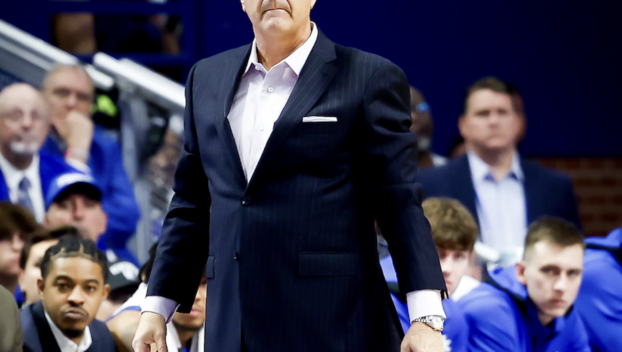

The John Calipari era is over at Kentucky. Calipari announced his resignation in a video posted Tuesday on ...

Despite cloudy weather across the Tri-State on Monday, close to 100 visitors made their way up to the ...

From WRIL The Claiborne County Sheriff’s Department and the Tennessee Bureau of Investigation joined forces in a death ...

LEXINGTON, Ky. (KT) — Aaron Bradshaw announced his plans to declare for NBA Draft and also entered the ...

Southeast Kentucky Community and Technical College (SKCTC) welcomed Dr. Ryan Quarles, president of the Kentucky Community & Technical ...

A Bell County deputy jailer has been charged with promoting contraband, first degree. 34-year-old Sonya Warren, of Pineville, ...

A Middlesboro woman in jail on trafficking and other charges is now facing five additional counts of trafficking ...

The Bell County Lady Cats snapped a three-game losing streak in dominating fashion with a 16-1 win at ...

Connor West drove in three runs with four singles in four at bats as visiting Barbourville overpowered Middlesboro ...

FRANKFORT, Ky. (KT) – Kentucky State Police Commissioner Phillip Burnett Jr. announced on Monday the promotion of Captain ...

FRANKFORT, Ky. (KT) – Secretary of State Michael Adams has announced that voter registration continues to surge ahead ...

By Steve Roark Columnist One of the most beautiful wildflowers to see in the Spring are trilliums, which ...

A former correctional officer at the Kentucky State Penitentiary in Eddyville has been sentenced for engaging in sexual ...

Secretary of State Michael Adams has announced that voter registration continues to surge ahead of the May 21 ...

Kentucky men’s basketball coach John Calipari is reportedly in “serious talks” with Arkansas about its head coaching vacancy. ...